Home2

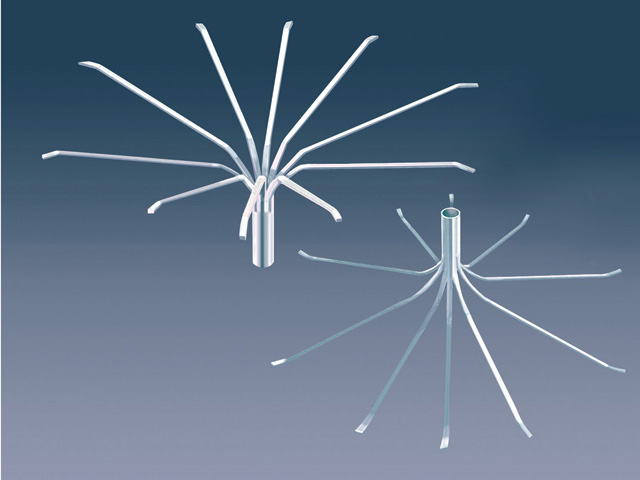

Evans Technology produces deep drawn, progressive and flat stampings in refractory and common metals. Lengths range from 0.030” to 13.5”, with O.D.’s from .015” to 14.000” and walls as thin as 0.003”. Drawn pieces can be as much as 1.500” deep.

From prototypes to millions of pieces, our production facilities are capable of tight tolerances at high speeds, using multi-station progressive and transfer machines, as well as stamping presses from 3 to 45 tons and hydraulic presses to 100 tons.

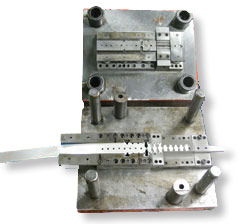

A complete in-house tool room permits rapid prototyping and production tool development. We can provide in-house engineering as well as production.

Stamped and deep drawn metal parts are from .030″ to 13.5″ diameter and up to 1.5″ deep.

See us at the Design2Part shows

Irving, TX | March 13 & 14

Atlanta, GA | March 27 & 28

Schaumburg, IL | May 8 & 9

Greenville, SC | September 10 & 11

Marlborough, MA | October 16 & 17

Let us help you with your next project from design to production.

From the D2P Trade Show

Tooling in Stock

We have tooling for more than 5000 deep drawn stampings, all in different sizes and shapes. We may very well have the tooling to make your part, or we may have tooling that can be adapted for your part. Either solution gives you considerable savings. Click here to learn more.